See user rating of ProManage in Gartner Peer Insights™ MES Market

Proven Roadmap for

your Success in Manufacturing

The following outline provides the comprehensive, unique & proven roadmap of how to modernize a manufacturing plant via ProManage new generation Smart Manufacturing Platform to insure success and sustainability.

Enhance Productivity with ProManage

End to End Smart Factory Solutions Platform for Proven Success

Years of Experience

Succeed Projects

Work Stations

Trusted by Global Brands

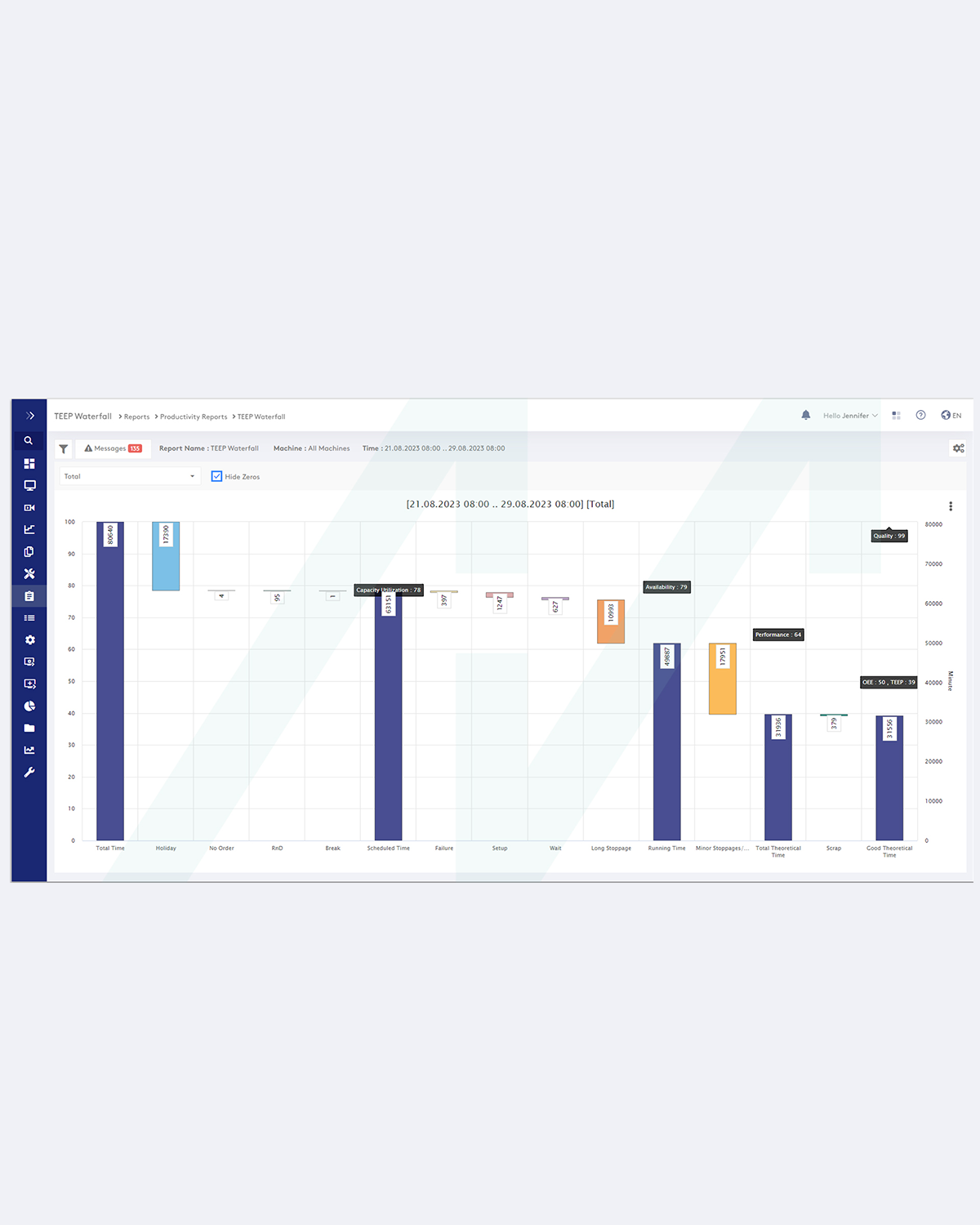

ProManage MES enhances production efficiency with real-time data and advanced analytics. Optimize your operations, reduce downtime, and boost productivity with our smart manufacturing solutions.